Service Overview

With a team of 50 highly qualified technocrats, we offer a diverse range of industrial automation services aimed at optimizing your industrial processes and enhancing productivity.

With a deep understanding of the latest technologies and industry best practices, our team is equipped to tackle even the most complex automation challenges with confidence and precision.

Whether you’re looking to streamline production processes, improve quality control, or reduce downtime, our team works closely with you to develop customized solutions that align with your objectives.

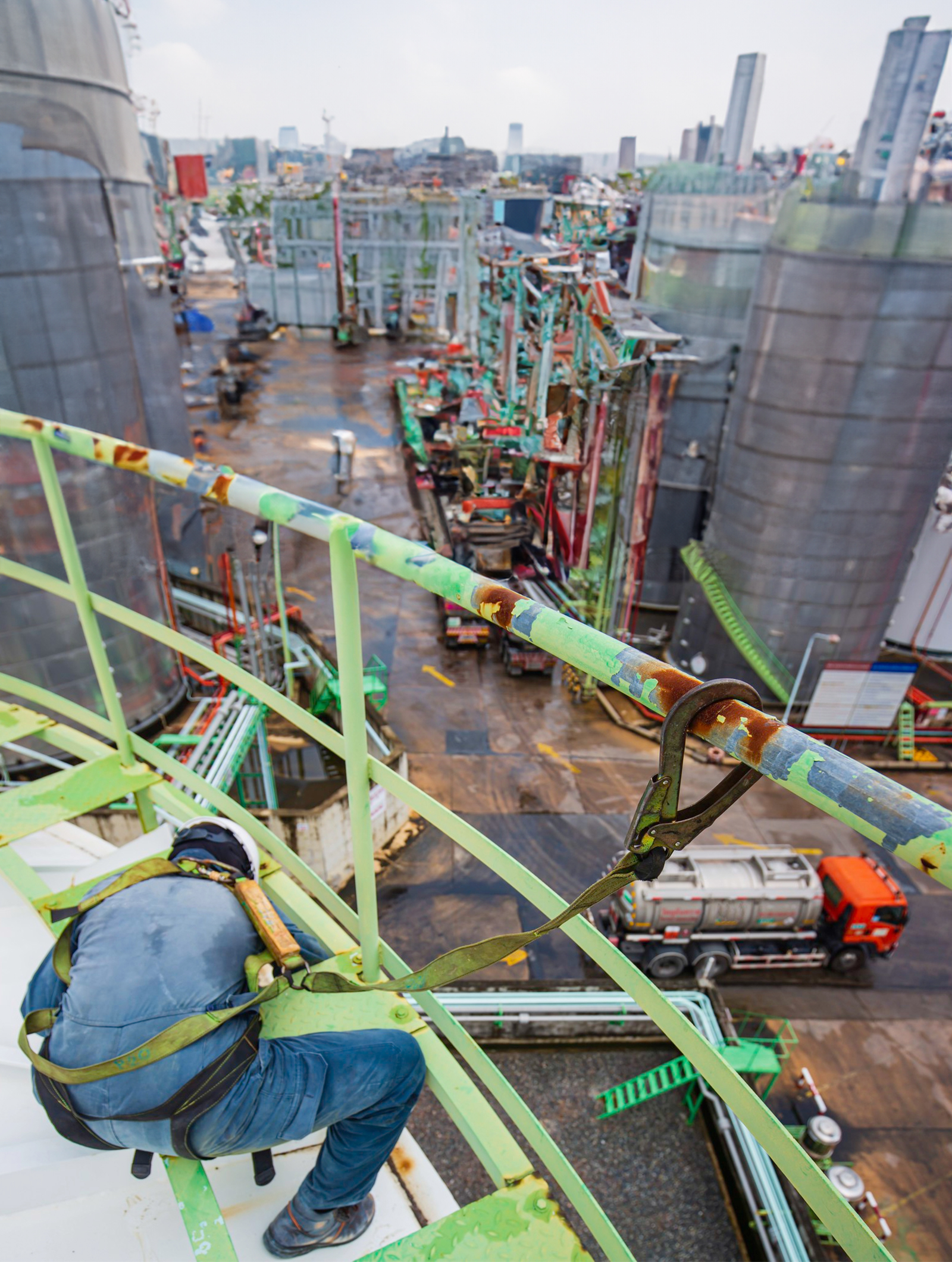

Engineering & Commissioning

From conceptualization to implementation, we specialize in engineering and commissioning services for IA projects. Whether it’s the installation of AC/DC Drives or PLC for Standalone applications, or the integration of complex systems incorporating AC/DC Drives, Servo Systems, PLC, and HMI technologies, we have the expertise to deliver results.

Process Automation

Our expertise extends to process automation using advanced systems such as DCS, PLC, HMI, and SCADA. By leveraging technologies from Siemens and Rockwell Automation, we help streamline your processes for improved efficiency and performance.

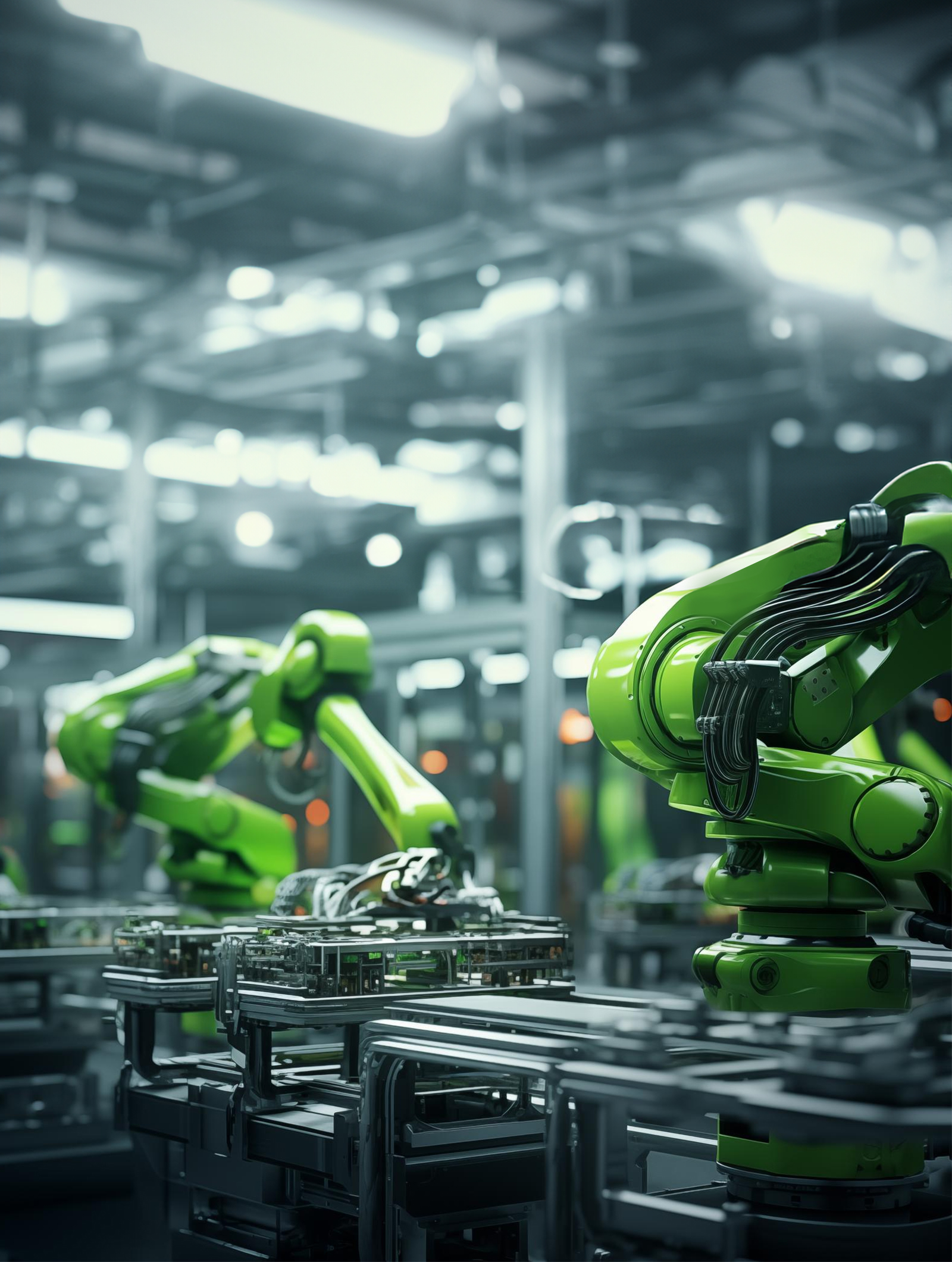

Factory Automation

We excel in factory automation solutions, utilizing state-of-the-art PLC and Drive systems from Siemens and Rockwell Automation. Our solutions are designed to optimize production processes, increase throughput, and minimize downtime

Breakdown Services and Maintenance Contracts

Ensuring the smooth operation of your automation systems is our top priority. Our team provides prompt breakdown services and offers annual maintenance contracts to keep your systems running at peak efficiency.

Our Technology

Partner in Industrial Automation

Collaborating with renowned technology

partners enables us to stay at the forefront of industry advancements, driving efficiency and excellence in our solutions.

As a trusted partner of SIEMENS, a global leader in automation technology, we have access to world-class Industrial Automation solutions engineered and manufactured for all industrial sectors. Our partnership with Siemens ensures that we deliver solutions of the highest quality and reliability, meeting the diverse needs of our clients with precision and efficiency.

Industrial Automation

Projects

From Various Sectors

- Clients

- Vedant Dyestuff & Intermediates Pvt Ltd, Dai-ichi Karkaria Ltd, Armaco, Baerlocher India Additives Pvt Ltd, Rossari Biotech Ltd, UPL Ltd, Advance Pharmaceutical Industries, Dorfketal, Elkem South-Asia Pvt Ltd

- Consultants

- Mott MacDonald Pvt. Ltd., Shroff and Associates(Engineers) Pvt. Ltd., Kastech Instrumentation, IBIC

- Projects

- More than 20 projects executed successfully Up to 2500 I/O’s

- System

- S7 400, S7 400 H (Hot Redundant), PCS 7 DCS system with fail safe modules, Redundant Server, Historian Server

- Software

- PCS7 with Batch Software for Complex Recipe Generation, WinCC SCADA for monitoring & control, SIMIT for Process Simulation, Asset Management System

- Application

- Colour dye unit, Ethoxylation Plant, Alkoxylation Plant, Fractionation Plant, SSP Plant, Speciality Chemicals for Textile & Detergent, PVC Additives, Vessels for Injectable Solution 21CFR complied

- Clients

- Ion-Exchange, Blue Star Ltd, Xylem Water Solutions India Pvt Ltd, Eureka Forbes, Vatech Wabag, Purita Water Solutions Pvt Ltd, Sparkle Cleantech Pvt Ltd, Om Ionexchange

- Projects

- More than 30 projects executed successfully Up to 6000 IO’s

- System

- Siemens S7 1500, S7 400H (Hot Redundant), Redundant Server Client architecture & HMI’s

- Software

- WinCC SCADA for monitoring & control

- Application

- Water & Waste Water Management system which includes Effluent treatment, sewage treatment, desalination, chilled water system

- Clients

- MRF Ltd, CEAT Ltd, ATC Tyres Ltd, Apollo Industries Ltd

- Projects

- More than 20 machines executed successfully

- Hardware & Software

- Compact logix CPU, Flex IO on Ethernet, IN view & HMI, S7 1200, S7 1500 PLC & HMI

- Application

- 11D Banbury Down Stream Automation, 45” Tyre Curing Press, Tyre Building Machine, Interfacing with Mixer PLC, Calendar Line, Tube Press Machine, 7-ply servicer, Windup Machine, Gum Strip Applicator, BEF Cooling Line, Visual Inspection System, Tyre Cleaning Machine

- Beverages

- 2D DPM Reading on metallic ring

- Clients

- MRF Ltd, CEAT Ltd, ATC Tyres Ltd, Apollo Industries Ltd

- Projects

- More than 20 machines executed successfully

- Hardware & Software

- Compact logix CPU, Flex IO on Ethernet, IN view & HMI, S7 1200, S7 1500 PLC & HMI

- Application

- 11D Banbury Down Stream Automation, 45” Tyre Curing Press, Tyre Building Machine, Interfacing with Mixer PLC, Calendar Line, Tube Press Machine, 7-ply servicer, Windup Machine, Gum Strip Applicator, BEF Cooling Line, Visual Inspection System, Tyre Cleaning Machine

- Beverages

- 2D DPM Reading on metallic ring

- Clients

- Vedant Dyestuff & Intermediates Pvt. Ltd., Dai-ichi Karkaria Ltd., Armaco, Baerlocher India Additives Pvt Ltd, Rossari Biotech Ltd., UPL Ltd, Advance Pharmaceutical Industries, Dorfketal, Elkem South-Asia Pvt. Ltd.

- Consultants

- Mott MacDonald Pvt. Ltd., Shroff and Associates(Engineers) Pvt Ltd,

- Projects

- More than 20 projects executed successfully Up to 2500 I/O’s

- System

- S7 400, S7 400 H (Hot Redundant), PCS 7 DCS system with fail safe modules, Redundant Server, Historian Server

- Software

- PCS7 with Batch Software for Complex Recipe Generation, WinCC SCADA for monitoring & control, SIMIT for Process Simulation, Asset Management System

- Application

- Colour dye unit, Ethoxylation Plant, Alkoxylation Plant, Fractionation Plant, SSP Plant, Speciality Chemicals for Textile & Detergent, PVC Additives, Vessels for Injectable Solution 21CFR complied

- Clients

- STT, NTT, Colt

- Projects

- More than 5 projects executed successfully Up to 3000 I/O’s

- System

- S7 400H (Hot Redundant), Fibre Optic Ring for IO devices, Redundant Server & Client architecture with Remote Web access

- Software

- WinCC SCADA for monitoring & control

- Application

- EPMS, Load Management for IT Load and Mechanical Load for Catcher & IBMS.

- Clients:

- Comp Engg & Exports, Kilburn Engg Ltd, Mojj Engg Systems Ltd

- Projects:

- More than 10 projects executed successfully Up to 500 I/O’s

- Hardware & Software:

- S7-400 with intelligent MCC (SIMOCODE) & VFD’s

- Application:

- Air Dryer Mining, Spray Dryer System, Evaporator

- Cement:

- Automation Solution for Cement Blending, Mixing & Packaging Plant utilising S7 300 R with WinCC SCADA for monitoring & control, for up to 700 IO’s

- Metal:

- Retrofitting of 20 HI Reversible Cold rolling Mill – Controls with SINAMICS DC Drives PLC S7 300. Line Speed 350 MPM. Tube Forming Mill – Using Siemens S7-300 PLC & SINAMICS – DC Drives.

- Distillery:

- Ethanol extraction process plant using Siemens PLC S7 400, VFD’s (Simatics V50), PVC coating lines with 19 nos. of VFD’s controlled with S7-300 PLC.

- Industrial Filtration System & Cleaning Machine:

- Automation with SIEMENS S7 400 H PLC with IO Redundancy.

- De-dusting System:

- Automation for removal of large amount of residue from Industrial Steel Furnaces.

- Boiler:

- Automation solution for Industrial Boiler monitoring & control

- Fertiliser:

- Automation solution for Water Soluble Fertiliser Plant using S7 400 H with WinCC SCADA for monitoring & control, for up to 500 I/O’s

- Food:

- Automation solution for Vegetable Oil Refinery utilising the Siemens S7 400 with WinCC SCADA for monitoring & control